Designing large new proteins with AI

New method for designing artificial proteins

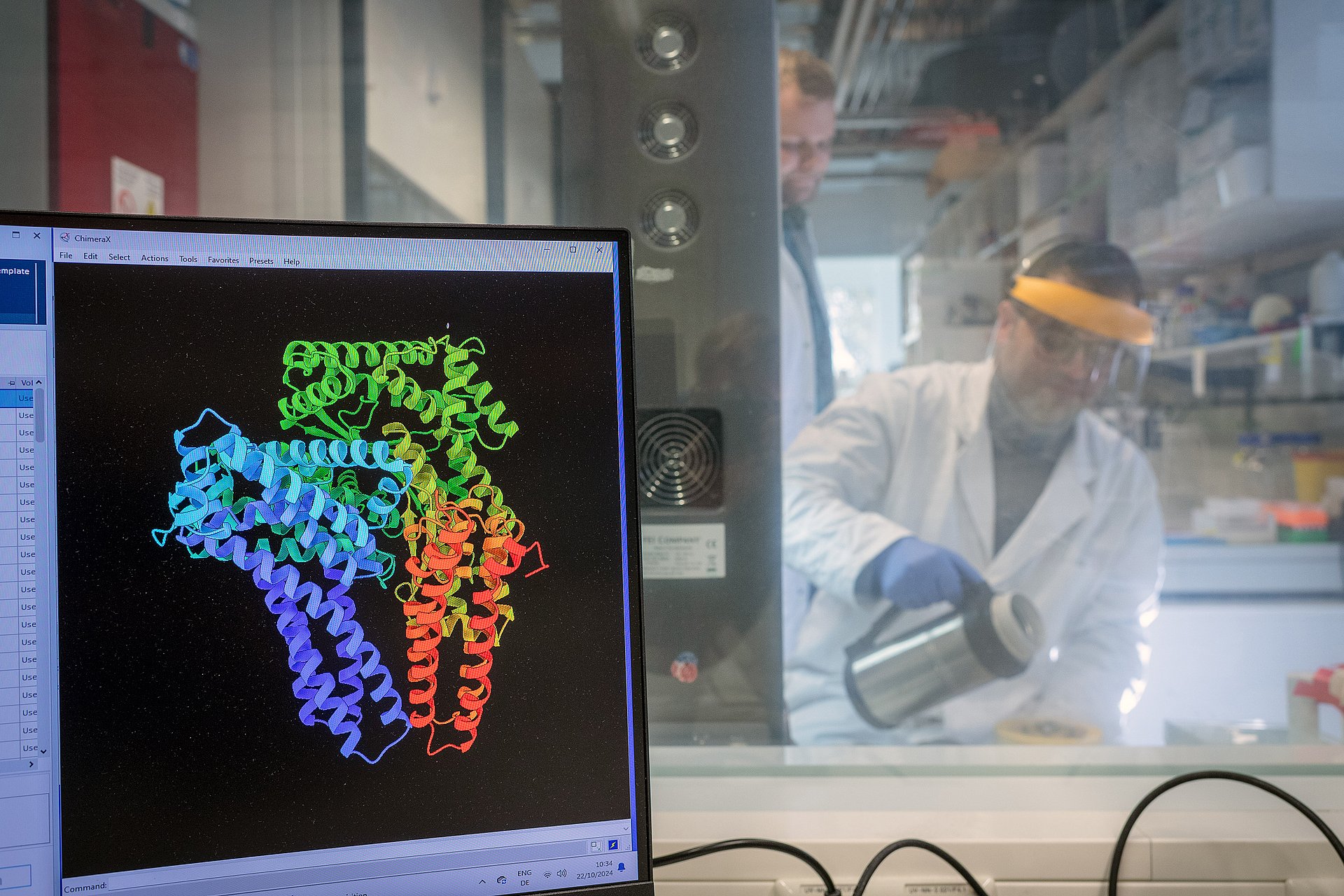

Left: Christopher Frank, first author of the new study. Right: Prof. Hendrik Dietz.

Whether as building blocks, transport systems, enzymes, or antibodies, proteins play a vital role in our bodies. Researchers are, therefore, trying to recreate them or to design so-called de novo proteins that do not occur in nature. Such artificial proteins are designed to bind to certain viruses or transport drugs, for example. Scientists are increasingly using machine learning to design them. Recently, advances in this field were honored with the Nobel Prize in Chemistry: This year's Nobel Prize went to David Baker, a pioneer of de novo protein design, and to the developers of the software Alphafold2 Demis Hassabis and John Jumper. This software makes it possible to predict protein structures on the computer with high accuracy.

An international team led by Hendrik Dietz, Professor of Biomolecular Nanotechnology at the Technical University of Munich (TUM), and Sergey Ovchinnikov, Professor of Biology at MIT, has now developed a method that uses Alphafold2's accurate structure prediction together with a so-called gradient descent approach for efficient protein design. It was published in the journal Science.

Gradient descent is a common method for model optimization. In a step-by-step process, it can be used to identify deviations from the desired target function and adjust the parameters until the optimal result is achieved. In protein design, gradient descent can be used to compare the structure of new proteins predicted by AlphaFold2 with the desired protein structure. This allows scientists to further optimize their newly designed amino acid chain and the resulting structure. The latter largely determines the stability and function of the protein and depends on subtle energetic interactions.

Virtual superposition of the building blocks

The new method makes it possible to design large new proteins better than before and to tailor them to the desired properties, for example, to bind precisely to other proteins. Their design process differs from previous approaches in several ways.

„We have designed the process for new proteins so that we initially ignore the limits of what is physically possible. Usually, only one of the 20 possible building blocks is assumed at each point of the amino acid chain. Instead, we use a variant in which all possibilities are virtually superimposed,“ says Christopher Frank, doctoral candidate at the Chair of Biomolecular Nanotechnology and first author of the study.

This virtual superposition cannot be directly translated into an actually producible protein. But it allows the protein to be iteratively optimized. “We improve the arrangement of the amino acids in several iterations until the new protein is very close to the desired structure," says Christopher Frank. This optimized structure is then used to determine the amino acid sequence that can actually be assembled to a protein in the laboratory.

The crucial test: how do the predictions hold up in real life?

The ultimate test for all newly designed proteins: does the actual structure correspond to the predicted construct and the desired function? Using the new method, the team designed more than 100 proteins virtually, produced them in the laboratory and tested them experimentally. „We were able to show that the structures that we designed are very close to the structures that are actually produced,” says Christopher Frank.

Using their new method, they were able to produce proteins consisting of up to 1000 amino acids. “This brings us closer to the size of antibodies, and – just as with antibodies – we can then integrate several desired functions into such a protein,” explains Hendrik Dietz. „These could, for example, be motifs for recognizing and suppressing pathogens.”

Frank C, Khoshouei A, Fuβ L, Schiwietz D, Putz D, Weber L, Zhao Z, Hattori M, Feng S, de Stigter Y, Ovchinnikov S, Dietz H: Scalable protein design using optimization in a relaxed sequence space. Science, October 2024. www.science.org/doi/10.1126/science.adq1741

-

Researchers from the following universities and institutions were involved in this research: Technical University of Munich (TUM), Massachusetts Institute of Technology (MIT), Harvard University, Fudan University, Changping Laboratory

-

Prof. Hendrik Dietz runs a research lab at the Munich Institute of Biomedical Engineering (MIBE), an Integrative Research Institute at TUM. At MIBE, researchers specializing in medicine, the natural sciences, engineering, and computer science join forces to develop new methods for preventing, diagnosing, or treating diseases. The activities cover the entire development process – from the study of basic scientific principles through to their application in new medical devices, medicines, and software.

-

This project was funded by: National Science Foundation, National Institutes of Health, European Research Council, Deutsche Forschungsgemeinschaft, Amgen, Education Commission of Shanghai Municipality, TUM Innovation Network Project: RISE

Technical University of Munich

Corporate Communications Center

- Carolin Lerch

- presse@tum.de

- Teamwebsite

Contacts to this article:

Prof. Dr. Hendrik Dietz

Technical University of Munich

Chair of Biomolecular Nanotechnology

Phone: +49 89 289 11615

dietz@tum.de