Project SeaClear for clean seafloors

Robots collect underwater litter

Our seas and oceans currently contain somewhere between 26 and 66 million tonnes of plastic waste, most of which is lying on the seafloor. This represents an enormous threat to marine plants and animals and to the ecological balance of the seas.

But removing waste from the waters is a complex and expensive process. It is often dangerous, too, because the work is generally done by scuba divers. The cleanup operations are also usually limited to the water surface. In the SeaClear Project, a team at TUM is working with eight European partner institutions to develop a robotic system capable of collecting underwater litter.

Four robots working together

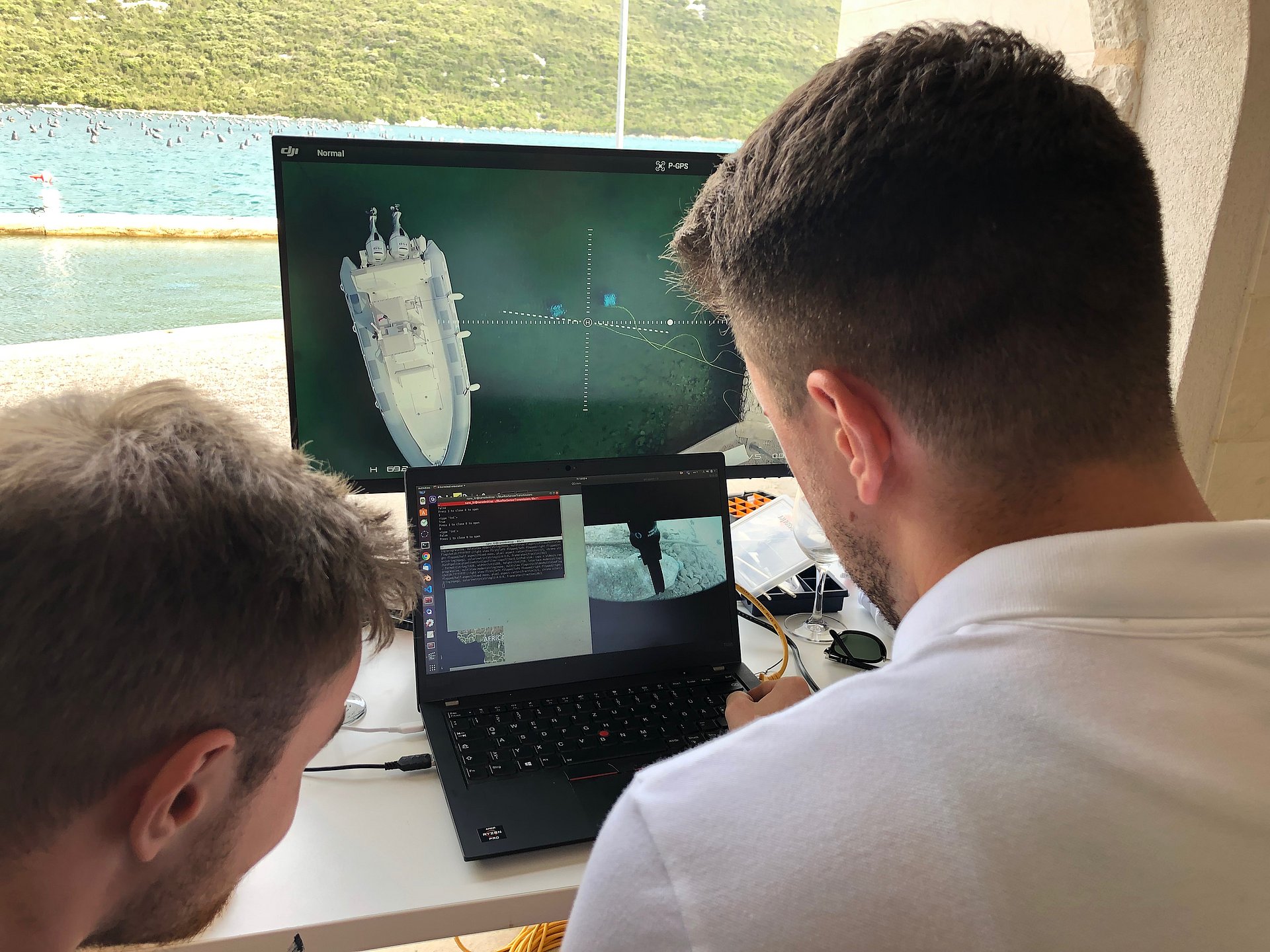

The system combines four robotic components: an autonomous surface vehicle performs an initial scan of the sea bottom and localizes large litter pockets. Next an observation robot is lowered into the water to detect undersea litter and transmit additional information to the computers such as close-up images of the sea bottom.

In clear water and with good visibility, an aerial drone is also used to identify further litter objects. The resulting data are combined to generate a virtual map. A collection robot then visits defined points on the map and picks up litter. It uses a gripper to place larger pieces in a basket that is towed to shore by the autonomous boat.

The challenge of currents

“Developing autonomous robots for underwater applications is a unique challenge” says Dr. Stefan Sosnowski, the technical director of the SeaClear project at the Chair of Information-oriented Control at TUM. That is because, in contrast to land-based applications, very special conditions prevail in the water. “When a piece of litter is identified and located, the robot needs to get close to it. To do so, it may need to overcome strong currents. The task of TUM in the SeaClear project is to enable the robot to move in the right direction.”

Efficient machine learning

To achieve this, the team is using machine learning methods. An artificial intelligence (AI) module performs calculations and learns the conditions under which the robot will move in certain ways. This makes it possible to predict its behavior precisely.

“Another challenge is that we don’t have the computing power at our disposal that we would on dry land,” says Prof. Sandra Hirche, director of the chair and SeaClear principal investigator. “We do not have links to large data centers with supercomputers. So we need highly efficient algorithms that run with limited resources. We are therefore working with high-efficiency sampling methods that arrive at precise predictions with minimal data. The AI system simply discards unnecessary information.”

90% success rate

When the SeaClear system is fully operational, it is expected to achieve 80% accuracy in classifying underwater litter and to successfully collect 90% of it. This is comparable to the results produced by scuba divers. The initial trials with the prototype were carried out in October 2021 in Dubrovnik, Croatia, where the water is clear and visibility is excellent. Further trials are scheduled in the port of Hamburg in May 2022.

P. Bevanda, S. Sosnowski, S. Hirche, "Koopman operator dynamical models: Learning, analysis and control", Annual Reviews in Control , 2021, 52, 197-212 , DOI:10.1016/j.arcontrol.2021.09.002.

- Prof. Dr.-Ing. Sandra Hirche

- Chair of Information-oriented Control

- SeaClear is an EU-funded Horizon 2020 project launched on January 1, 2020. It will run until December 2023 and has an overall budget of approx. 5 million euros. Eight partners from five countries and 49 researchers are participating in the project. The eight partners: TU Delft, Hamburg Port Authority, TU Cluj-Napoca, Subsea Tech, Technical University of Munich (TUM), Fraunhofer CML, University of Dubrovnik and DUNEA. Official Website: https://seaclear-project.eu/

- High-resolution images: https://mediatum.ub.tum.de/1638148

- Videos of the Project

Technical University of Munich

Corporate Communications Center

- Christine Lehner

- presse@tum.de

- Teamwebsite

Contacts to this article:

Prof. Dr.-Ing. Sandra Hirche

Technical University of Munich (TUM)

Chair of Information-oriented Control

Tel: +49 (89) 289 25723

Hirche@tum.de

www.tum.de