Start-up Kinexon enables more precise refereeing decisions

High-tech sensors for the European Championship ball

When the final of the European Football Championship will be played on Sunday, the referee could once again take center stage. A surprise for most TV viewers at this European Championship: during the review of controversial scenes on the sidelines, a curve graphic reminiscent of an ECG appeared on the monitor for the first time. It shows if and when the ball was touched so that the referees can penalize a handball, for example.

This is made possible by a high-precision motion sensor suspended in the ball – developed by TUM spin-off Kinexon. Founded in 2012, the start-up is an expert in sensor technology, software and automation. Its sensor chip transmits 500 times per second where the ball is, how fast it is moving, how it is turning and whether it is being touched. The behavior of the ball is not affected, the chip weighs only three grams.

The associated software provides the referee team with evaluations so that they can make quicker and better decisions, and TV broadcasters with information such as how hard Harry Kane's shot on goal was. Highest precision, speed and reliability of the technology were decisive reasons for the partnership between the ball producer Adidas and Kinexon.

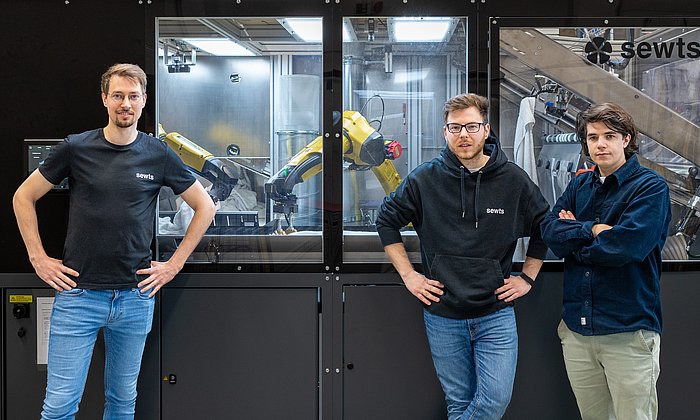

Digital twins of entire factories

Soccer is by no means the only sport that Kinexon equips. "More than 400 teams use our chips, whether in basketball, ice hockey or handball," says founder and CEO Dr. Oliver Trinchera. The sensors are sewn into the players' jerseys. This enables the clubs to evaluate movement sequences and performance data. In addition to tactical and performance-related analysis, the clubs also use them to prevent injuries. "In the US basketball league NBA, we have a market share of 85 percent."

The sports sector is not even the company's core business. The focus is on production and logistics. "We can be involved wherever something is moving," says Trinchera. Kinexon creates digital twins of entire factories so that processes can be analyzed and automated in real time. Trinchera explains an example: "In automotive manufacturing, we orchestrate large fleets of autonomous transport robots. In doing so, we ensure that transportation orders are completed in the fastest and most efficient way possible. If challenges such as blocked routes arise, the software reacts in fractions of a second." BMW, for example, has digitized its entire production process with the technology.

Oliver Trinchera learned how to combine technical expertise with an understanding of the market on TUM’s Management and Technology degree program, where students study both business administration and a tech subject – electrical engineering and information technology in Trinchera's case. Trinchera got the tools he needed to found the company at the Center for Digital Technology and Management. The CDTM offers an additional course of study in which students work with industry partners on problems from the real business world and at the same time learn how to create innovations and set up their own company. Trinchera and co-founder Dr. Alexander Hüttenbrink prepared the start-up while doing their doctorate at the Chair of Financial Management and Capital Markets. Today, Kinexon has more than 300 employees and a second location in Chicago in addition to Munich.

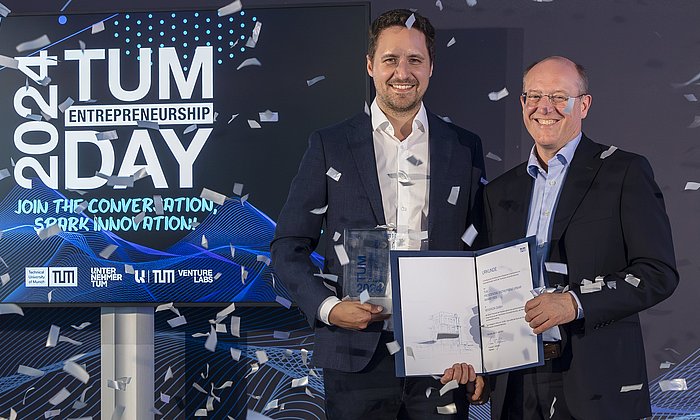

Every year, more than 70 technology-oriented companies are founded at TUM. TUM and UnternehmerTUM support start-ups with programs that are precisely tailored to the individual phases of founding - from the conception of a business model to management training, from market entry to a possible IPO. The TUM Venture Labs offer start-up teams from major technology fields an entire ecosystem in direct connection with research. Up to 30 teams can use the TUM Incubator to prepare for the launch of their company. UnternehmerTUM invests in promising technology companies with its own venture capital fund and offers the MakerSpace, a 1,500 square meter high-tech workshop for prototyping.

Technical University of Munich

Corporate Communications Center

- Klaus Becker

- klaus.becker@tum.de

- presse@tum.de

- Teamwebsite